steel making (secondary)

VOD Unit

Vacuum Argon Decarburization (VOD)/ Argon Oxygen Decarburization (AOD) is primarily a process used for making stainless steel. In VOD, the vessel works with oxygen injection and subsequently with vacuum treatment for decarburization, while in AOD, the initially melted metal is transferred to the AOD vessel where the process of decarburization, reduction and desulphurisation takes place.

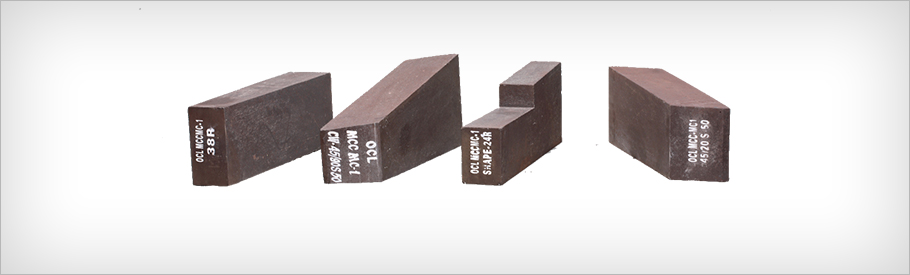

OCL’s Magnesia Chrome bricks are specially made to resist the severity of VOD/AOD operations such as high operating temperatures, low basicity of slag and severe turbulence of steel.

- Magnesia Dolomite bricks.

- Direct bonded and Re-bonded fused bricks.

- Magnesia Carbon bricks.

- High strength Magnesia Chrome and Direct bonded Magnesia Chrome bricks.

- Rebonded fused grain Magnesia-Chrome.

- Specially designed Purging Plug.

Special Features

- Our Magnesia Dolomite bricks; and direct bonded & re-bonded fused magnesia chrome bricks are specially made to resist the severity of VOD operations such as high operating temperature, low basicity slag and severe turbulence of steel.

- Magnesia Dolomite bricks for AOD converters made from synthetic Magnesia Dolomite clinker have high density and purity, and hence exhibit uniform physical, chemical and thermal properties. These bricks also show excellent hydration resistance, high corrosion resistance to secondary refining slags with low basicity and high hot abrasion resistance to metal.

Ladle Furnace

A Ladle Furnace or Ladle Refining Furnace is used to refine the quality of liquid metal to make high quality steel by raising temperature and adjusting the chemical composition of molten metals.

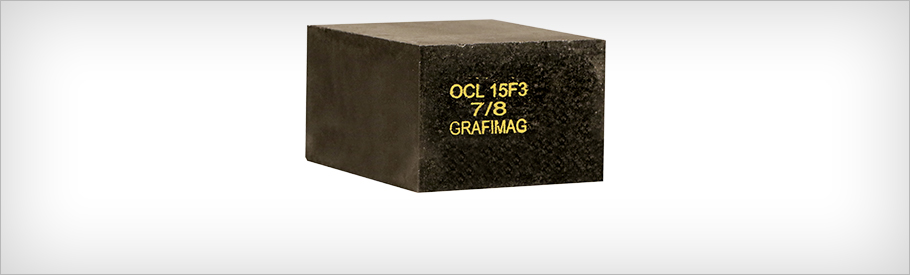

OCL’s Magnesia Carbon bricks with controlled residual expansion are specially recommended for the middle zone and bottom of the ladle furnace to prevent joint erosion and metal penetration.

- Magnesia Carbon bricks.

- Alumina Magnesia Carbon bricks

- Low Carbon and Alumina Spinel bricks for work lining.

- Chrome Magnesite and Fireclay for safety linings.

- Basic Gunning and Ramming Masses.

- Conventional and Low Cement Castables for safety along with peripheral lining.

- Precast High Alumina Castable blocks.

- Alumina Spinel bricks for ladle and High Alumina plastic for closing the retainer.

Special Features

- Our Magnesia carbon bricks with improved carbon bonding and special characteristics like low coked porosity, high coked cold crushing strength, excellent corrosion, erosion, thermal shock & oxidation resistance and high hot strength are suitable for different zones depending on operational severity.

- Our Alumina Magnesia Carbon bricks with controlled residual expansion are recommended for the middle zone and bottom of the ladle furnace to prevent joint erosion and metal penetration.

RH Degasser

An RH Vacuum Degasser is an equipment for swift degassing of large amounts of molten steel. It is used for mass production of high purity steel, realizing decarburization and heating by injecting pure oxygen gas into the vacuum vessel.

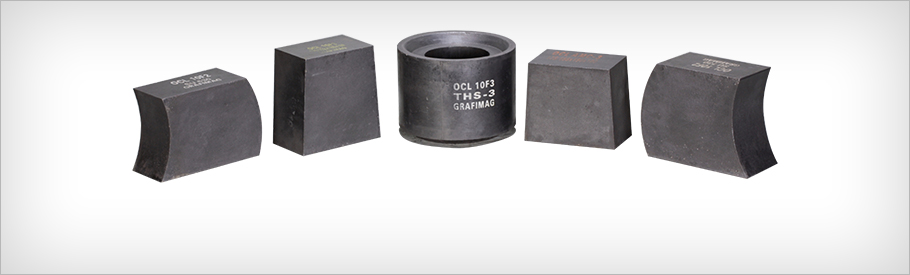

Made with high purity raw materials, OCL’s Magnesia Chrome bricks provide high resistance to thermal spalling, high hot strength, high resistance to corrosion and impedes infiltration of slag and metal.

- Fused direct bonded Magnesia Chrome bricks.

- Low Cement Castables.

- 42% Alumina bricks.

- Basic Mass and Mortar.

Special Features

- Our bricks are made from high purity raw materials with spinel bonding that provides high resistance to thermal spalling, high hot strength, high resistance to corrosion and impedes infiltration of slag & metal.

- Fused direct bonded Mag-Chrome and Low Cement Castables for Snorkels.

- Fused direct bonded Mag-Chrome for Lower Vessel.

- Direct bonded Mag-Chrome for Middle Vessel.

- Direct bonded Mag-Chrome for Upper Vessel.

Special Features

- Provides high hot strength.

- High Resistance to Corrosion.

- Impedes infiltration of Slag & Metal.

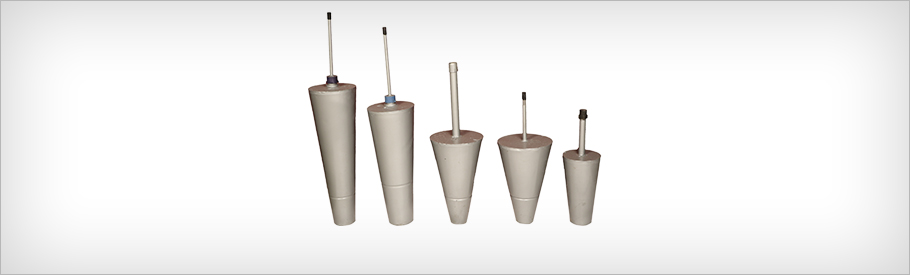

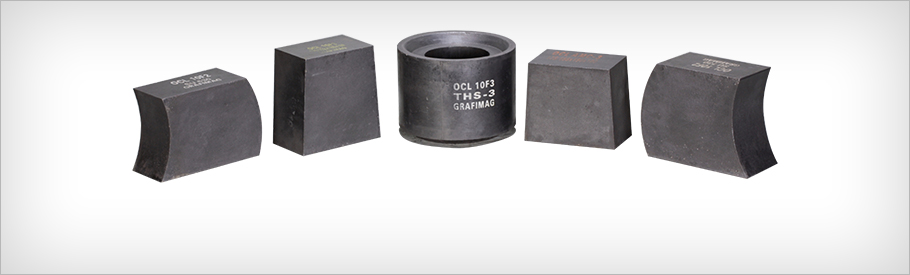

Purging Plug System

Purging blocks are fitted at the bottom of the ladle to purge inert gas (Argon) for temperature homogenization, chemistry homogenization and absorbed gas removal.

OCL’s Purging Plugs have minimal risk of metal infiltration and offer high blowing capacity of 1000-1200 Lt./min.

We offer a range of high performance Directional Purging Plugs with customized design and secondary metallurgical operations which have been adopted by various steel plants.

- High Alumina and Alumina Spinel based plugs.

Our Purging Plugs are based on tabular Alumina, Alumina Magnesia Spinel and Alumina Chrome based materials.

Special Features

- High resistance to slag and abrasion.

- High thermal shock resistance.

- Low RTE values.

- Numbers of purging slits vary from 20-30.

- Slit Thickness of 0.25-0.30 mm.

- Minimum risk of metal infiltration.

- High Blowing capacity of 1000-1200 Lt./min.

AOD Unit

Vacuum Argon Decarburization (VOD)/ Argon Oxygen Decarburization (AOD) is primarily a process used for making stainless steel. In VOD, the vessel works with oxygen injection and subsequently with vacuum treatment for decarburization, while in AOD, the initially melted metal is transferred to the AOD vessel where the process of decarburization, reduction and desulphurisation takes place.

OCL’s Magnesia Chrome bricks are specially made to resist the severity of VOD/AOD operations such as high operating temperatures, low basicity of slag and severe turbulence of steel.

- Magnesia Dolomite bricks.

- Direct bonded and Re-bonded fused bricks.

- Magnesia Carbon bricks.

- High strength Magnesia Chrome and Direct bonded Magnesia Chrome bricks .

- Rebonded fused grain Magnesia-Chrome.

Special Features

- Our Magnesia Dolomite bricks; and direct bonded & re-bonded fused magnesia chrome bricks are specially made to resist the severity of VOD operations such as high operating temperature, low basicity slag and severe turbulence of steel.

- Magnesia Dolomite bricks for AOD converters made from synthetic Magnesia Dolomite clinker have high density and purity, and hence exhibit uniform physical, chemical and thermal properties. These bricks also show excellent hydration resistance, high corrosion resistance to secondary refining slags with low basicity and high hot abrasion resistance to metal.