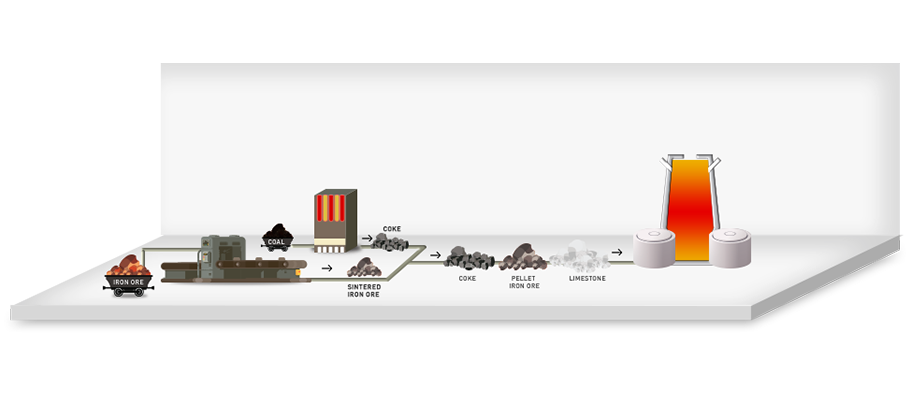

iron making

Sinter Plant / Pelletisation Plant

Sinter plants agglomerate iron ore fines (dust) with other fine materials at a high temperature, to create a product that can be used in a blast furnace. The final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals.

OCL’s high alumina bricks for sinter plant are known for their dimensional accuracy and high Refractoriness Under Load (RUL).

- High Alumina bricks.

- Castables.

Special Features

'OCL-made' bricks and castables for Sinter plant have –

- High abrasion and wear resistance.

- High mechanical strength.

- Increased Refractoriness Under Load (RUL).

Blast Furnace

The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is blown into the bottom.

OCL’s high alumina bricks for blast furnace are characterized by good dimensional accuracy, high mechanical strength and spalling resistance.

OCL’s silica bricks for blast furnace stove offer good dimensional tolerance along with high compressive and mechanical strength.

A hot-blast stove is a facility to supply hot air to a blast furnace continuously. In the combustion (heat accumulation) phase, heat energy in hot exhaust gas from a burner is accumulated in checker bricks and, in the ventilation phase, a large quantity of air is blown through the checker bricks to raise the temperature of air.

Drawing from our experience in manufacturing silica bricks for coke oven, we have developed world-class silica bricks for heavy duty Blast Furnace Stoves that has won the confidence of world-known stove designers like DCE, DME, Paulwurth, PRIMETAL, NSC, among others.

- Silica bricks.

- High Alumina checker bricks.

- Fireclay bricks.

Our products for Blast Furnace Stoves have been supplied to a number of projects worldwide and received wide appreciation from domestic and overseas customers for timely delivery, good packaging and dimensional accuracy of products.

Special Features

‘OCL-made’ bricks for Blast Furnace Stoves have –

- High stability.

- Good resistance to corrosion, erosion and thermal shock.

- Resistant to Creep at high temperature.

A blast furnace trough system consisting of a main trough, skimmer, iron runner, slag runner and tilting runner is used to transfer the molten iron tapped from the blast furnace to torpedo cars.

- Castables for BF Runner Endless Lining.

Our high performing Al2O3-SiC-C based ultra-low cement castables have been developed in collaboration with TYK Japan. These castables are tailor-made for specific working environments and have performed up to 1.7 million and 0.5 million tons in 2000 m3 and 3200 m3 blast furnaces.

Special Features

With high purity grains, specially graded Silicon Carbide & graphitic additives that minimize abrasion and penetration, ‘OCL-made’ castables for Blast Furnace Runners have –

- Superior abrasion resistance.

- Crack resistance.

Coke Oven

Coke oven is an oven for the conversion of coal into coke by heating coal in the absence of air so as to distill the volatile ingredients. The waste heat of a coke oven is well adapted for this purpose. Through our collaboration with Dr C OTTO of Germany for initial know-how and subsequent intensive R&D efforts, we have established ourselves as a leading Coke Oven Silica Refractory manufacturer in the world, with an impressive list of supply references, in both, domestic and overseas markets.

With high thermal stability and low creep, OCL’s silica bricks have been used for coke ovens around the world, for over five decades.

- Silica bricks

- High Alumina bricks

- Fireclay bricks

- Castables

With our wide experience, we can supply Silica refractories for 4-7 Mtr tall coke oven batteries that meet national and international specifications such as MECON, DIN, JIS, BS, PW & NSC and can also manufacture in national and international designs, such as MECON, OTTO, GIPROKOKS, KARL STEEL etc.

Special Features

'OCL-made' Silica bricks for Recovery Coke Oven have:

- Low residual quartz ( <1%)

- Low creep even at 1550°C/50 hours

- Consistency & smooth thermal expansion, even up to 1550°C

- High hot strength

- Low statistical variation in property data ensured by quality assurance system

- High dimensional accuracy enabling accurate and fast construction.

- Silica bricks

- High Alumina bricks

- Fireclay bricks

Here too, with our wide experience, we can supply Silica Refractories that meet national and international specifications such as, DIN, TSOA,SUN COKE, RAYTHEON , Jewell-Thompson etc.

Special Features

‘OCL-made’ Silica bricks for Non-Recovery Coke Oven have –

- Low residual quartz ( <1%)

- Low creep even at 1550°C

- Consistency & smooth thermal expansion even up to 1550°C

- High hot strength

- Low statistical variation in property data ensured by quality assurance system

- High dimensional accuracy enabling accurate and fast construction

- High Alkali resistance