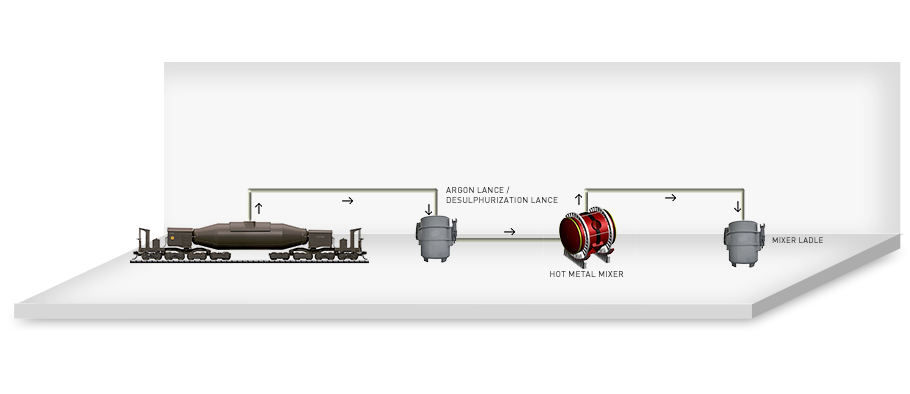

hot metal transport

Torpedo Ladle

Torpedo ladle cars are used to transfer molten iron from the iron-making unit to the steel making section. Torpedo ladle can also be used as a refining vessel for de-sulfurization/de-phosporization by injection of powdered reagents into molten iron through lance. The reagents react with the sulfur/phosphor present in molten iron and separate out from iron as slag.

Made with special additives, OCL’s Alumina-Silicon-Carbide bricks for torpedo ladles have high cold crushing strength, giving them great strength in striker areas.

- High Alumina Bricks.

- Al-SiC-C bricks.

- Torpedo Gunning.

- Shotcrete mass.

- Castables.

The most vulnerable areas of the Torpedo Ladle vessel are striker pad, metal zone, slag zone & lip area. Our Alumina-SiliconCarbide-Carbon (ASC) / High alumina 85% Al2O3 bricks are specially suitable for metal & slag zones; and special ASC bricks with high impact strength are ideal for striker pads. For repair and maintenance of ladle lip area in hot conditions, we offer high alumina gunning castables.

Special Features

- High alumina bricks blended with fused material gives good corrosion resistance to metal & slag.

- ASC bricks made with special additives have high cold crushing strength, as a result its impact strength is high for striker areas.

- Gunning castable for lip area has good stickability properties as well as good thermal spalling resistance.

Hot Metal Ladle

Hot metal ladle is used to transport hot iron from Blast Furnace to Hot Metal Mixer. No treatment is undertaken in this ladle.

Made with special grade andalusite and low iron bauxite, OCL’s high alumina bricks give good corrosion resistance to metal & slag in hot metal ladle.

- Al-SiC-C Bricks.

- High Alumina Bricks.

- Fireclay Bricks.

Time and again, our Alumina-SiliconCarbide-Carbon (ASC) bricks and High Alumina bricks have proven to be great cost-economic solutions that have maximized the life of the ladle.

Special Features

- High alumina bricks made with Andalusite /low iron Bauxite gives good corrosion resistance to metal & slag.

- ASC bricks made with special additives have high cold crushing strength.

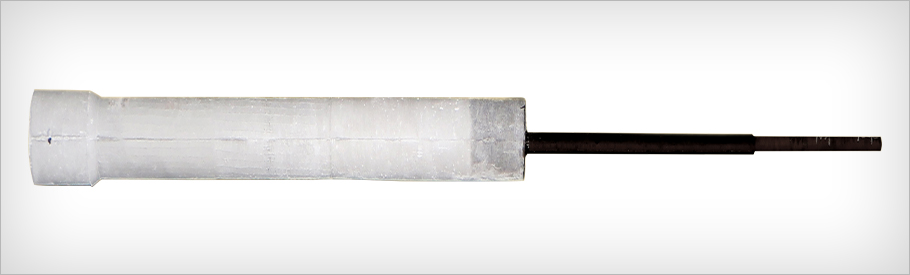

Lance

Lances are used in steel industry for argon rinsing stations, Desulphurisation of hot metal and oxygen lancing for temperature control of hot metal and to make homogenous clean steel.

We manufacture ULCC-based monolithic lances for varied operating conditions, such as monolithic rinsing lances for (a) argon and nitrogen bubbling in steel and (b) oxygen blowing in steel treatment process.

Meticulously designed centre & Tuyere pipes for strong construction, minimum pipe bending with excellent erosion and superior spalling resistance make OCL’s Lances popular among users.

- We offer a number of monolithic powder injection lances for de-siliconisation, de-phosphorisation and de-sulphurisation

Special Features

'OCL-made' lances offer:

- Excellent erosion resistance and superior spalling resistance.

- Meticulously designed centre & tuyere pipes for strong construction and minimum pipe bending.

- Increased thickness at slag line and lance tip for balanced erosion.

- Minimum differential expansion between castable and centre pipe for prevention of cracks during treatment.