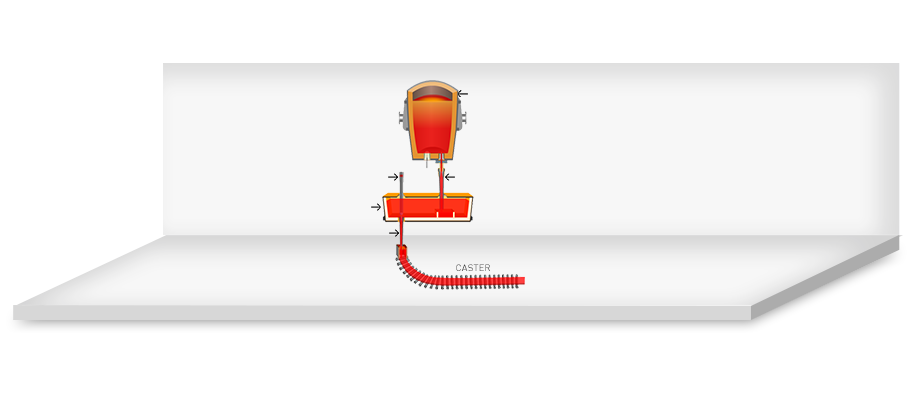

Continuous Casting

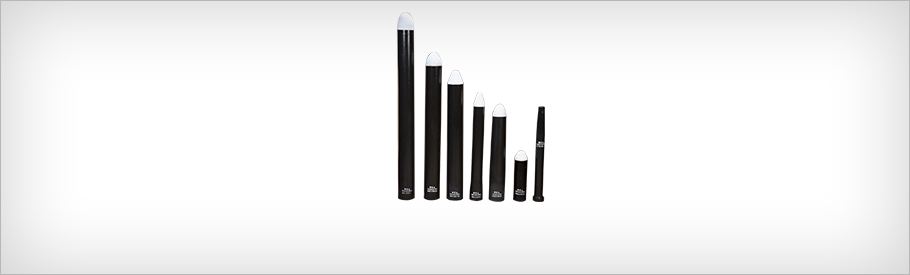

Ladle Shroud

Ladle shrouds are special equipment that protect and control the flow of steel from Ladle to Tundish.

OCL’s Ladle Shrouds offer superior corrosion and spalling resistance, ensure low carbon and nitrogen pick-up, making them an ideal choice.

Made with Isostatically pressed Alumina Carbon composites, our Ladle shrouds are tailor-made to meet specific requirements of customers. Incidentally, we are known to offer the widest range of tailor-made designs and our shrouds come in all types, shapes and sizes –

Special Features of various types of ladle shrouds

- Composite type shrouds offer superior corrosion resistant material in slag zone and spalling resistant material in body for longer sequence casting.

- Shrouds with steel encasing in neck area provide additional strength.

- Y-shaped shrouds help in neck strengthening & reducing Nitrogen pick up.

- Shrouds with argon injection system through in-built channel / porous ring / groove/ steel CAN help reduce Nitrogen pick up.

- Shrouds with pyroplastic sealing gasket reduce Nitrogen pick up.

- Bell shaped design helps reduce turbulence in tundish.

Sub-Entry Nozzle(SEN)

SEN is used to guide the flow of steel from Tundish to mould during continuous casting. Materials like Zirconia Carbon and Magnesia-carbon are used at different zones to make it suitable for longer sequence casting.

With isostatically pressed carbon composites and magnesia carbon in the seat area, OCL’s Sub Entry Nozzles are most popular for making special grades of steel.

- Made with Isostatically pressed Alumina-Zirconia–Carbon composites, we offer tailor-made SEN designs to meet specific customer requirements.

Special Features

- SEN with Zirconia-Graphite at “Mould powder area” offers excellent corrosion resistance.

- With Magnesia Carbon in seat area, it is used in special grades of steel.

- Flat type SEN is particularly useful for narrow sections.

- With effective use of nano-zirconia at slag band, it is used for achieving higher life.

Mono Block Stopper (MBS)

Mono Block Stoppers are used to control the flow of steel through the sub-entry nozzle or the tundish nozzle.

OCL’s Monoblock Stoppers are known for their excellent performance, especially for high Ca ppm steel and they are also tailor-made for individual plant requirements.

Made with Isostatically pressed Alumina Carbon or Magnesia Carbon composites, we tailor-make MBS to suit specific customer requirements. We also offer -

- MBS with and without argon injection system.

- Composite type MBS with high spalling resistant material at the body and erosion resistant material at the nose.

- Specially designed MBS for foundries.

Special Features

- Special material like Zirconia Carbon / Magnesia Carbon used at Tundish slag zone acts as corrosion resistant material.

- MBS with Magnesia-carbon nose can be used for high Ca ppm steel and High corrosion resistant material at the nose for MS & SS grade steel.

Tundish

Tundish is an intermittent vessel between the ladle and the mould. It acts as a reservoir where liquid steel gets residence time before casting. This helps non-metallic inclusions to float on the surface and allows clean steel to be cast.

- High alumina bricks.

- High Alumina Low Cement Castables.

Special Features

- High alumina bricks made with Andalusite /low iron Bauxite gives good corrosion resistance to metal & slag.

- ASC bricks made with special additives have high cold crushing strength.