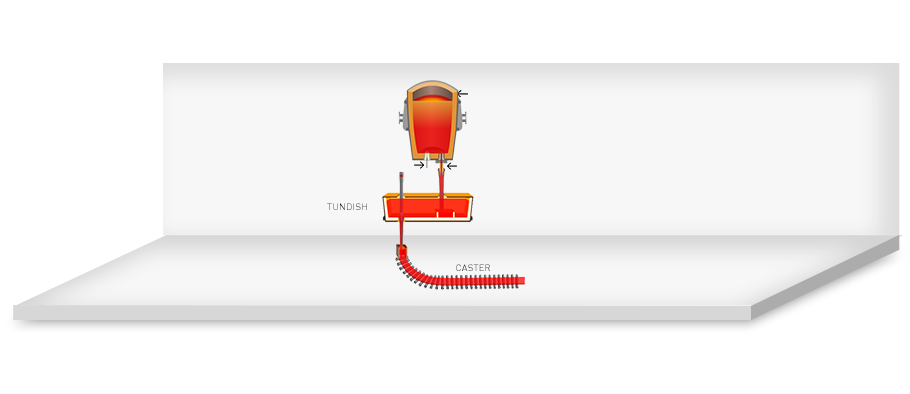

flow control

Slide Gate System

Slide Gate Systems are used to control the flow of molten steel from ladles.

With our wide experience, we have been manufacturing slide gate plates and nozzles (in both conventional and new generation designs) for all types of steel grades.

With a higher spigot area that helps in getting high face pressure, OCL’s Slide Gate Mechanisms cause less chances of metal penetration and can provide almost double life than others.

- Alumina Carbon, Alumina Zirconia Carbon, Alumina Spinel Carbon and Magnesia Carbon based slide gate plates and nozzles

- Plates and Nozzles designed with inserts made of Zirconia/Spinel for higher life and specially crafted for new generation plates.

- TN Mechanism - new generation slide gate mechanism, best suited for new generation plates that are user friendly and give higher life, with greater safety.

Special Features

- Different qualities of slide gate plates and nozzles –

- Plates and Nozzles with inserts –

- TN Mechanism –

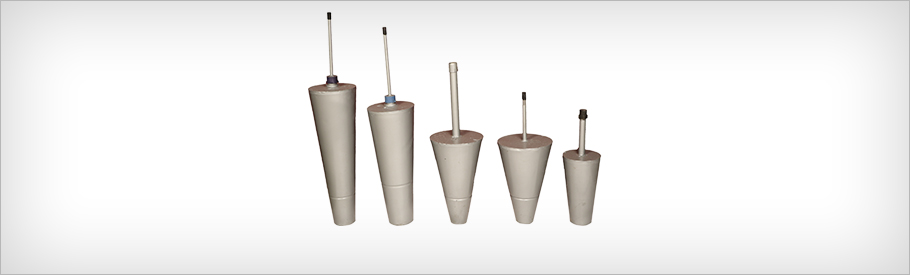

Purging Plug System

Purging blocks are fitted at the bottom of the ladle to purge inert gas (Argon) for temperature homogenization, chemistry homogenization and absorbed gas removal.

OCL’s Purging Plugs have minimal risk of metal infiltration and offer high blowing capacity of 1000-1200 Lt./min.

We offer a range of high performance Directional Purging Plugs with customized design and secondary metallurgical operations which have been adopted by various steel plants.

- High Alumina and Alumina Spinel based plugs.

Our Purging Plugs are based on tabular Alumina, Alumina Magnesia Spinel and Alumina Chrome based materials.

Special Features

- High resistance to slag and abrasion.

- High thermal shock resistance.

- Low RTE values.

- Numbers of purging slits vary from 20-30.

- Slit Thickness of 0.25-0.30 mm.

- Minimum risk of metal infiltration.

- High Blowing capacity of 1000-1200 Lt./min.