Smelting

Depending on the smelter that you use please make a selection below:

Flash Smelter

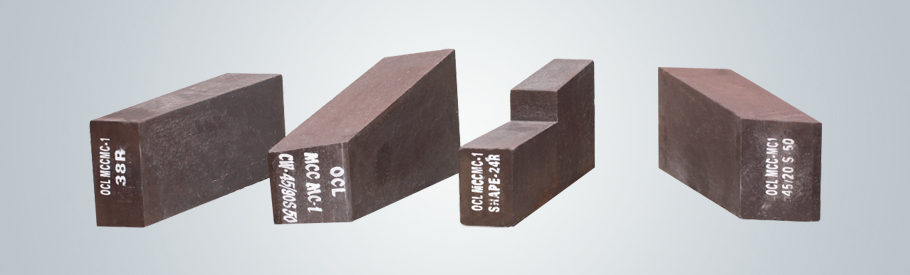

This is a special type of furnace from construction point of view where primary smelting is done. This furnace requires Mag- Chrome co-sinters with high degree of spinel formation and direct bonding.

Magnesia chrome bricks with high degree of spinel formation and bonding providing resistance to high hot abrasion.

- Direct bonded Magnesia Chrome bricks

- Insulating refractory bricks in the back up lining

- Castables and mortars

Special Features

- Highly resistant to high hot abrasion

- Highly resistant to pyrochemical stresses

- Helping in preventing sulphur attack in uptake.

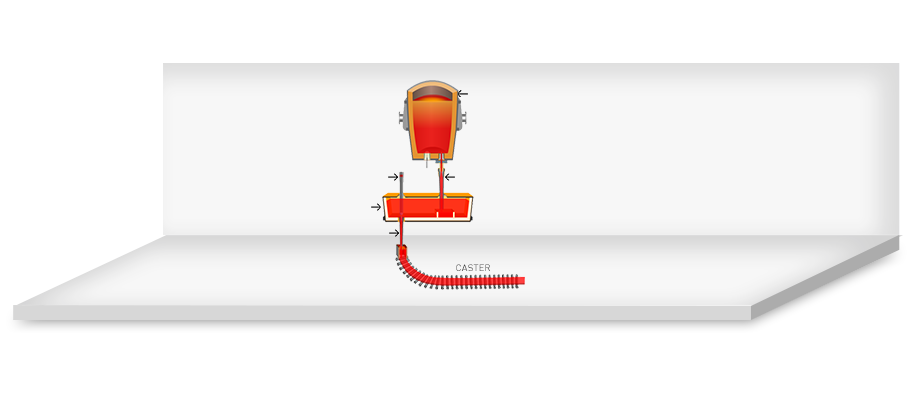

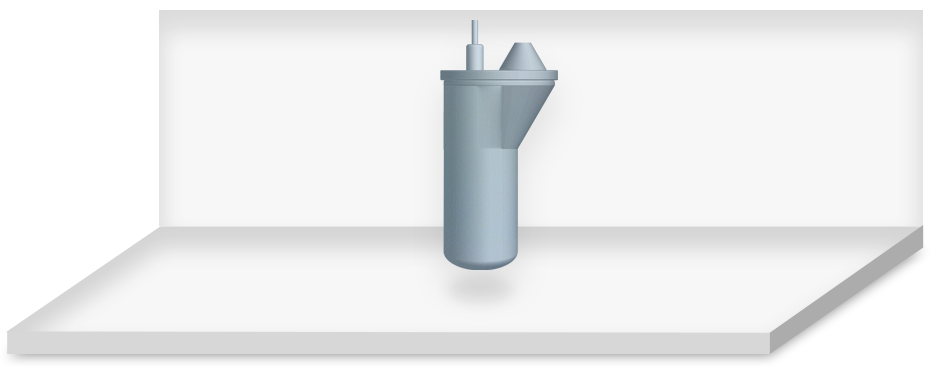

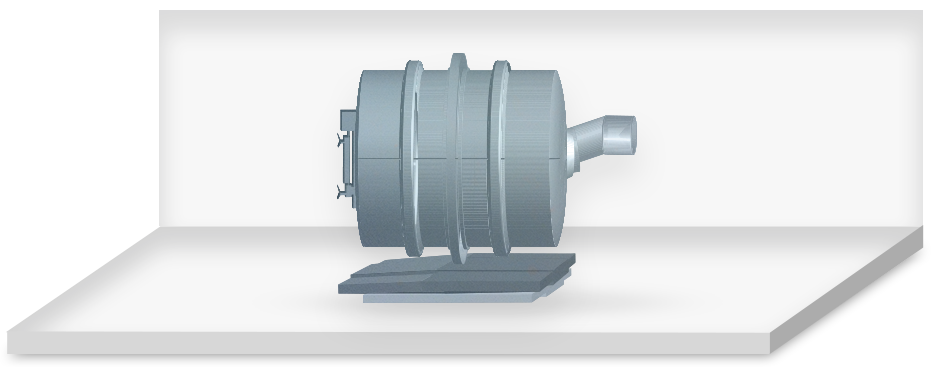

Isasmelt Reactor

An Isasmelt reactor is an upright-cylindrical shaped steel vessel with molten bath of slag, matte or metal (depending on the application) at the bottom of the furnace. A steel lance is lowered into the bath through a hole in the roof of the furnace, and air or oxygen-enriched air is injected through the lance into the bath. Because of the vigorous agitation caused in the bath, high quality of refractory is needed due to extremely acidic slag.

Dalmia-OCL’s Alumina-SiC- Carbon bricks are an excellent solution due to their resistance to erosion and chemical attack from the acidic slag of the furnace.

- Direct bonded Magnesia Chrome bricks

- Alumina-SiC–Carbon bricks

- Insulating refractories for back-up lining

- Ultra-low cement based castables and mortars.

Special Features

- Highly resistant to turbulent effect, erosion and chemical attack

- Highly resistant to pyrochemical attack and thermal stress from slag splash at the upper level of the furnace.

Reverberatory Furnace

This is a smelting furnace used in copper production treating either roasted calcine or raw copper sulfide concentrate, which encounters similar type of thermo-mechanical stresses as a flash smelter.

Dalmia-OCL’s magnesia chrome bricks are known for their superior resistance to sulfur dioxide attack.

- Direct Bonded Magnesia Chrome bricks

- Castables and mortar

Special Features

- Excellent resistance to pyrochemical attack at slag bath region

- Direct bonded bricks show excellent resistance to suplfur dioxide attack

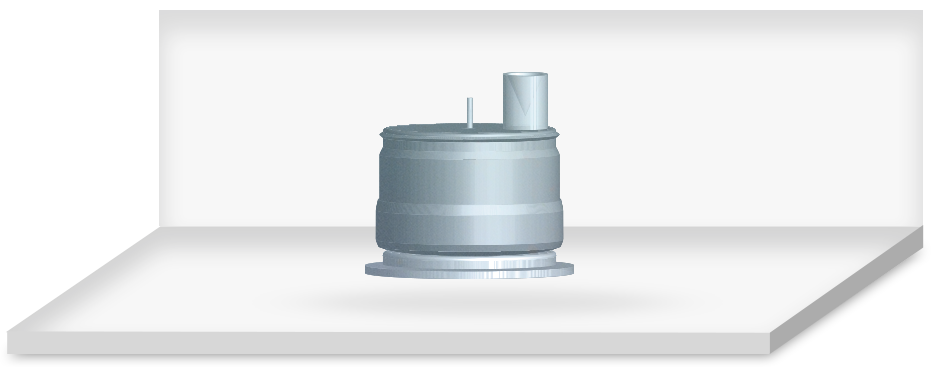

Mitsubishi Furnace

This is the most advanced industrial manifestation of copper making process which employs three furnaces (smelting, electric slag and converting furnace) connected by continuous gravity flow of molten metal.

Dalmia-OCL’s Alumina-SiC-Carbon bricks provide excellent resistance to pyrochemical attacks.

- Direct Bonded Magnesia Chrome bricks

- Alumina-SiC-Carbon bricks

- Insulating refractories

- Castables and mortars.

Special Features

- Direct bonded bricks show excellent resistance to sulfur dioxide attack

- Provide excellent resistance to pyrochemical attack