Converting

Depending on the converter that you use please make a selection below:

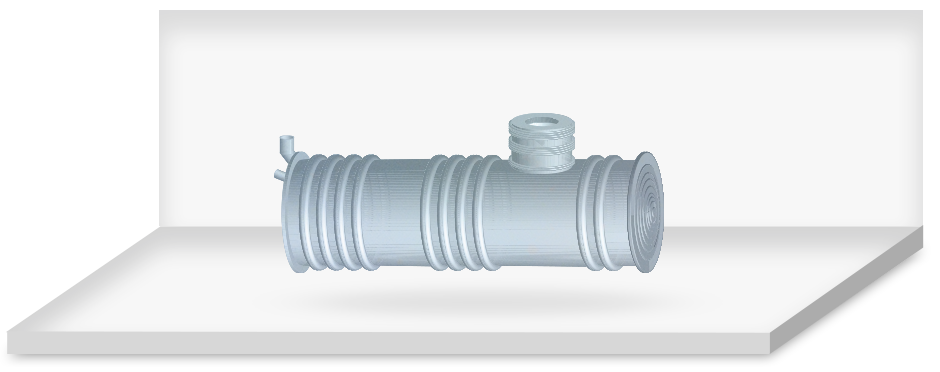

Teniente Converter

The teniente converter is a horizontal steel barrel with submerged tuyere. This kind of primary smelting is basically used to produce blister copper or high grade matte in a continuous process combined with optimized energy balance.

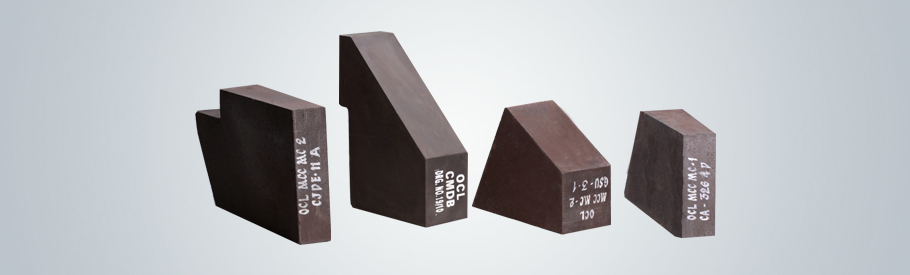

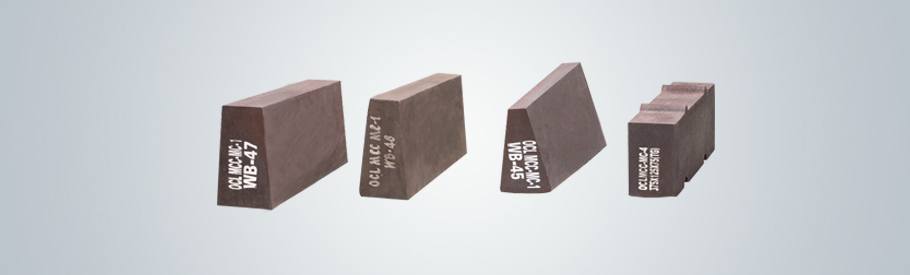

Dalmia-OCL’s direct bonded Magnesia Chrome bricks are highly resistant to corrosion and infiltration caused by untreated flux.

- Direct bonded Magnesia Chrome bricks with magnesia chrome sinters

- Castables and mortar mixes

Special Features

- High resistance to thermal spalling and corrosion in tuyere zone

- High resistance to corrosion and infiltration caused by untreated flux

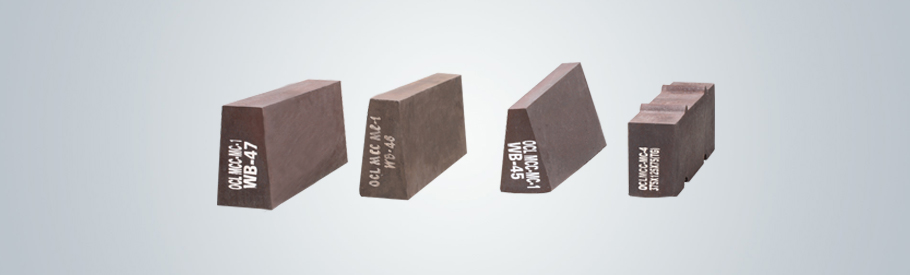

PS Converters

In this horizontal converter, blister copper is produced. As it undergoes different thermo-mechanical and pyrochemical stresses, refractories used here need to have high resistance to liquid infiltration and hot erosion.

Dalmia-OCL’s Magnesia Chrome bricks are highly resistant to liquid infiltration and hot erosion in the tuyere zone caused by high bath agitation.

- Direct bonded Magnesia Chrome bricks.

- Mortar mixes

Special Features

- Resistance to liquid infiltration, thermal shock and thermo-mechanical stresses

- High resistance to liquid infiltration and hot erosion in tuyere zone.

- Resistance to corrosion and infiltration of slag, matte and copper oxide.

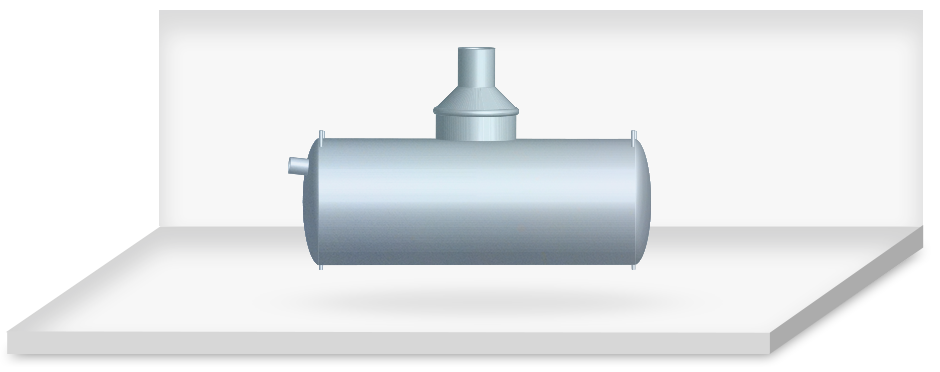

Top Blown Rotary Converter

This converter operates in inclined position, which rotates about its horizontal axis for treatment of copper smelter anode slimes to recover precious metal content.

These direct bonded Mag-Chrome bricks are excellent resistance to heavy erosion .

- Direct bonded Magnesia Chrome bricks

- Castables and mortar mixes

Special Features

- Excellent resistance to heavy erosion, chemical attacks and thermal shocks

- High resistance to infiltration of slag, matte and oxide

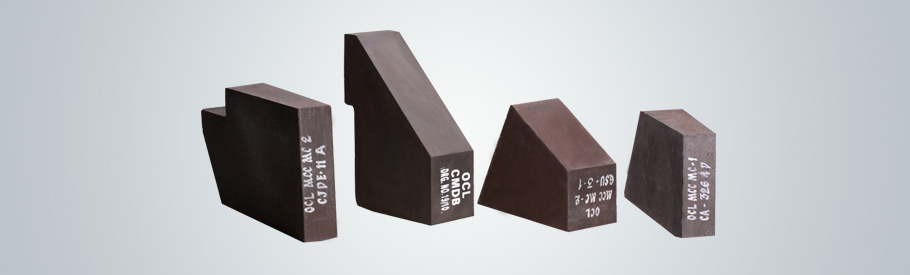

Mitsubishi Converter

In this converter, copper matte and the limestone are reacted with oxygen enriched air to form blister copper and then separated from the slag by difference in specific gravity.

Direct bonded Magnesia Chrome bricks from Dalmia-OCL are highly resistant to heavy erosion.

- Direct bonded Magnesia Chrome bricks

- Castables and mortar mixes

Special Features

- Excellent resistance to heavy erosion

- High resistance to infiltration of slag, matte and oxide

Flash Converter

In this furnace, blister copper is produced from matte, a process similar to the flash smelter process. In the flash converter, lime is also used to form calcium ferrite slag with high copper oxide.

Dalmia-OCL’s Magnesia Chrome bricks are highly resistant to pyrochemical stresses caused by fayalatic slag and matte infiltration in the settler.

- Magnesia Chrome bricks made with fused magnesia chrome grains

- Castables and mortars

Special Features

- High resistance to high hot abrasion caused by the turbulence of gas laden particles along with thermal stresses in the reaction shaft.

- High resistance to pyrochemical stresses caused by fayalatic slag and matte infiltration in the settler.