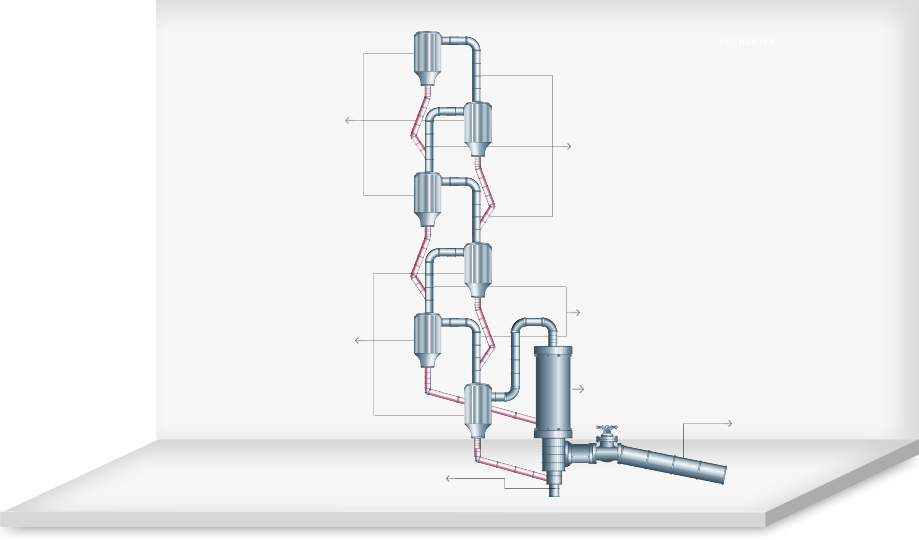

Preheater

Preheater & Calciner Vessels

Installed upstream of the calciner and the rotary kiln, the preheater is a tower that heats up the raw mix with hot gases from the kiln. Main components of the preheater tower are cyclones which are conical vessels with openings at the top and bottom. Hot gas laden with raw mix is released tangentially inside a cyclone and particles separated through centrifugal force go down through a valve at the bottom, while clean gas passes up through an opening at the top called vortex finder. Depending on the requirement, there could be a single string or double strings of preheaters along with several stages of cyclones.

Made with high purity materials, Dalmia’s high alumina bricks are well-known for their superior abrasion and thermal shock resistance.

- Bricks

- Castables

Special Features

- Superior abrasion and thermal shock resistance.

- High mechanical strength.

- Increased Refractoriness Under Load (RUL).

Tertiary Air Duct (TAD)

A Tertiary Air Duct is a part of the Preheater that bypasses the kiln and is used to divert the combustion air required for the calciner from the kiln hood. Here, tertiary airflow is controlled using various gates.

Dalmia’s anti-coating high alumina bricks provide excellent resistance to abrasion along with coating repellence.

- Bricks

- Bricks for critical areas

- Castables

- Castables for critical areas

Special Features

- Excellent resistance to abrasion and alkali attack.

- Anti-coating properties.

Lower Cyclones

The riser duct recycles heated air from lower cyclone stages and within the kiln itself, thus improving the thermal efficiency and reducing fuel costs.

Dalmia’s SiC based anti-coating castables are highly resistant to abrasion and provide a maximum service temperature of 1600℃.

- Bricks

- Castables

- Castables for critical areas

Special Features

- Superior strength

- Abrasion and alkali resistance

- High refractoriness

Lower Riser Ducts

The riser duct recycles heated air from lower cyclone stages and within the kiln itself, thus improving the thermal efficiency and reducing fuel costs.

Dalmia’s SiC based anti-coating castables are highly resistant to abrasion and provide a maximum service temperature of 1600℃.

- Bricks

- Castables

- Castables for critical areas

Special Features

- Superior strength

- Abrasion and alkali resistance

- High refractoriness

Kiln Inlet Chamber

The kiln inlet chamber (also called smoke chamber) is at the base of the preheater where the preheater ends and rotary kiln starts. Here, raw mix coming down from the preheater goes to the kiln and gases come from the kiln and go up the preheater. Due to continuous circulation of gases rich in alkali or sulphur, refractories in this area are prone to coating formation and chemical attack.

Dalmia’s SiC based castables have good anti-coating properties which provide a long life to kiln’s inlet chamber.

- Bricks

- Castables

- Castables for critical areas

Special Features

- Superior strength

- High purity with resistance to alkali, abrasion and thermal shock

- High refractoriness

Upper Riser Ducts

The riser duct recycles heated air from lower cyclone stages and within the kiln itself, thus improving the thermal efficiency and reducing fuel costs.

Dalmia’s SiC based anti-coating castables are highly resistant to abrasion and provide a maximum service temperature of 1600℃.

- Bricks

- Castables

- Castables for critical areas

Special Features

- Superior strength

- Abrasion and alkali resistance

- High refractoriness

Upper Cyclones

The riser duct recycles heated air from lower cyclone stages and within the kiln itself, thus improving the thermal efficiency and reducing fuel costs.

Dalmia’s SiC based anti-coating castables are highly resistant to abrasion and provide a maximum service temperature of 1600℃.

- Bricks

- Castables

- Castables for critical areas

Special Features

- Superior strength

- Abrasion and alkali resistance

- High refractoriness