Cooler

Cooler

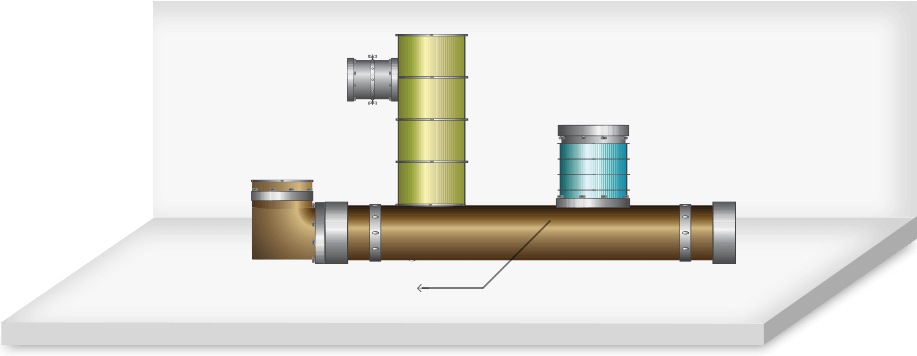

In the kiln free lime (C) and belite (C2S) react to form alite (C3S) which is the main component of cement giving it strength. However, the kiln discharges clinker at around 1300℃ and at that temperature the reaction is reversible. The role of the cooler is to rapidly reduce the temperature of alite preventing it from breaking into belite and free lime. This, inside the cooler, the clinker is cooled quickly subjecting it to cooling air, and thereby stopping the reverse reaction.

Dalmia’s low cement based special castables with a maximum service temperature of 1600℃ are highly resistant to abrasion and alkali attack.

- Castables

- Castables for critical areas

Special Features

- High purity with abrasion resistance, thermal shock resistance and resistance to alkali attack

- High hot strength

- Anti-coating properties

Electric Arc Furnace

The Electric Arc Furnace (EAF) is a vessel where steel is produced by electro fusion arcing with the help of graphite electrodes. Operating as a batch melting process, the charge materials used for melting are steel scraps, sponge iron, DRI and other such materials, either alone or in combination.

Refractories used in this vessel are exposed to high temperatures which are most severe in the hot spot zones. Thus, refractories for this vessel should have high oxidation resistance, erosion and thermal shock resistance; and the charge pad area should have high impact resistance to withstand the impact of steel scraps fed to the furnace.

There are two types of Electric Arc Furnace (EAF) designs based on Tapping Device –

1.EAF with Launder Tap, where the molten metal is teemed from the furnace through a Launder system.

2.EAF with EBT System, where the molten metal is teemed through a Tap hole device from the bottom of the furnace.

OCL’s Magnesia Carbon bricks with high oxidation resistance are most suited to handle severe temperatures in electric arc furnaces.

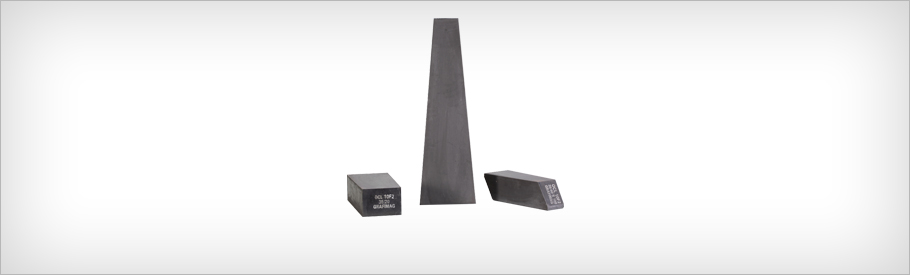

- Magnesia Carbon Bricks.

- Gunning, Hot Patching and Fettling Masses.

- EBT Blocks.

We offer complete refractory packages for EAF such as for metal zone, slag zone, hot spot bricks, tap hole tube sleeves along with monolithic refractories. We also offer several qualities in precast refractories that have high thermal shock resistance. Our team of experts recommend qualities based on the types of feed material and operating conditions of the furnace.

Special Features

- Our EBT tap tubes are made of magnesia carbon with very high purity magnesia and graphite that offer superb oxidation, corrosion and abrasion resistance.

- For the bottom part of tap tubes which are exposed to high abrasion during tapping of molten steel, our Alumina Silicon Carbide Carbon (ASC) quality bricks have proved to be excellent end bricks for their high abrasion resistance and thermal shock resistance.

- For use between tap hole block and tap hole sleeve, our ramming masses come with high corrosion resistance, bonding strength and volume stability.

- For EAF roof delta, our Al2O3-Cr2O3 based castables can withstand operational severity and provide significant improvement of roof life. Our castables are characterized by -

Purging Plug System

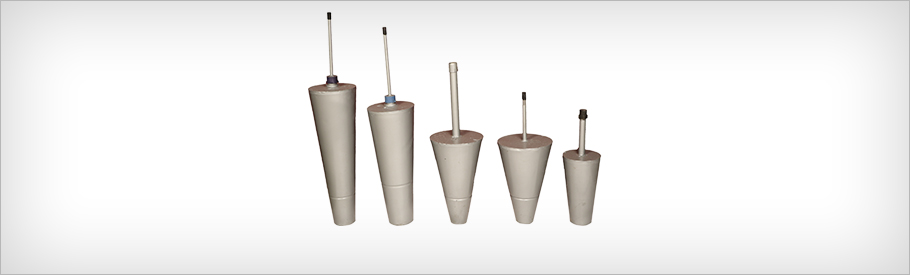

Purging blocks are fitted at the bottom of the ladle to purge inert gas (Argon) for temperature homogenization, chemistry homogenization and absorbed gas removal.

OCL’s Purging Plugs have minimal risk of metal infiltration and offer high blowing capacity of 1000-1200 Lt./min.

We offer a range of high performance Directional Purging Plugs with customized design and secondary metallurgical operations which have been adopted by various steel plants.

- High Alumina and Alumina Spinel based plugs.

Our Purging Plugs are based on tabular Alumina, Alumina Magnesia Spinel and Alumina Chrome based materials.

Special Features

- High resistance to slag and abrasion.

- High thermal shock resistance.

- Low RTE values.

- Numbers of purging slits vary from 20-30.

- slit Thickness of 0.25-0.30 mm.

- Minimum risk of metal infiltration.

- High Blowing capacity of 1000-1200 Lt./min.