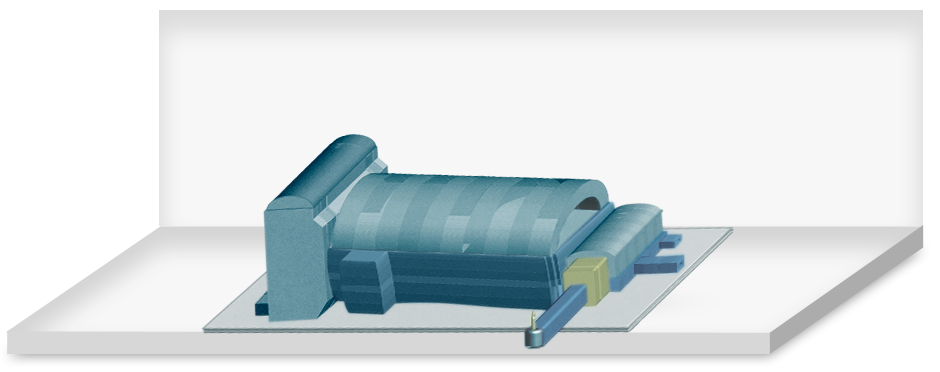

Glass Melting

Glass Melting Tank

Glass melting tanks are specially designed furnaces where molten glass is formed and retained at the correct temperature for further processing. Glass melting furnaces are lined with high quality refractories to withstand high temperatures and resist the thrust of molten glass.

Leading glass manufacturers prefer OCL’s super duty silica bricks for the crown due to their low thermal conductivity and excellent insulation resulting in significant energy savings.

These are the solutions for Crown and Super Structure:

- Super duty silica bricks

- Fused silica bricks

- Silica insulation bricks

- Silica mortar and hot patching mass

- High alumina (98% to 99%)

Special Features:

- Low flux factor (<0.5%)

- High resistance to corrosion and thermal shock

- Good creep resistance and low thermal conductivity

- High resistance to penetration of alkali vapour encountered during furnace operation & volume stability at furnace operating temperature

- High RUL & PCE, low RQ (<0.5 %) leading to uniform thermal expansion

- Shapes are made with almost zero dimensional tolerance